In a world that’s rapidly advancing, the distribution industry is at the forefront, ever-evolving to meet increasing demand. As the lifeline of e-commerce and global trade, warehouses must be durable, scalable, and flexible. Sunward’s pre-engineered steel buildings are the perfect solution for establishing distribution warehouses, with an array of benefits to fulfill diverse industry needs.

Distribution warehouses require vast, unobstructed spaces for efficient operations. With our steel buildings offering wide clear-spans (up to 200’ wide), you can confidently accommodate racking systems, machinery, and ensure smooth movement of goods. The high overhead clearance is perfect for vertical storage, optimizing the use of space.

Balancing Practicality and Aesthetic Appeal

Not just workhorses, Sunward’s steel warehouse buildings can be tailored to match your brand’s aesthetic. The buildings are not only functional and sturdy but can also be designed to have a modern and polished appearance. Our steel buildings are built to endure, while providing an engaging environment for employees.

Sunward’s distribution warehouse steel buildings are ideal for:

- Distribution Centers

- Fulfillment Centers

- Cross-docking facilities

- Bulk storage

- Cold storage

Our buildings are cost-effective, easy to maintain, and can be expanded to adapt to your growing needs. Our expert team will assist you in complying with local building codes and can connect you with reliable contractors to ensure a smooth building process.

Discover the possibilities with Sunward Steel’s distribution warehouse steel buildings. Call phone number to discuss your requirements, or visit our homepage for a free price quote.

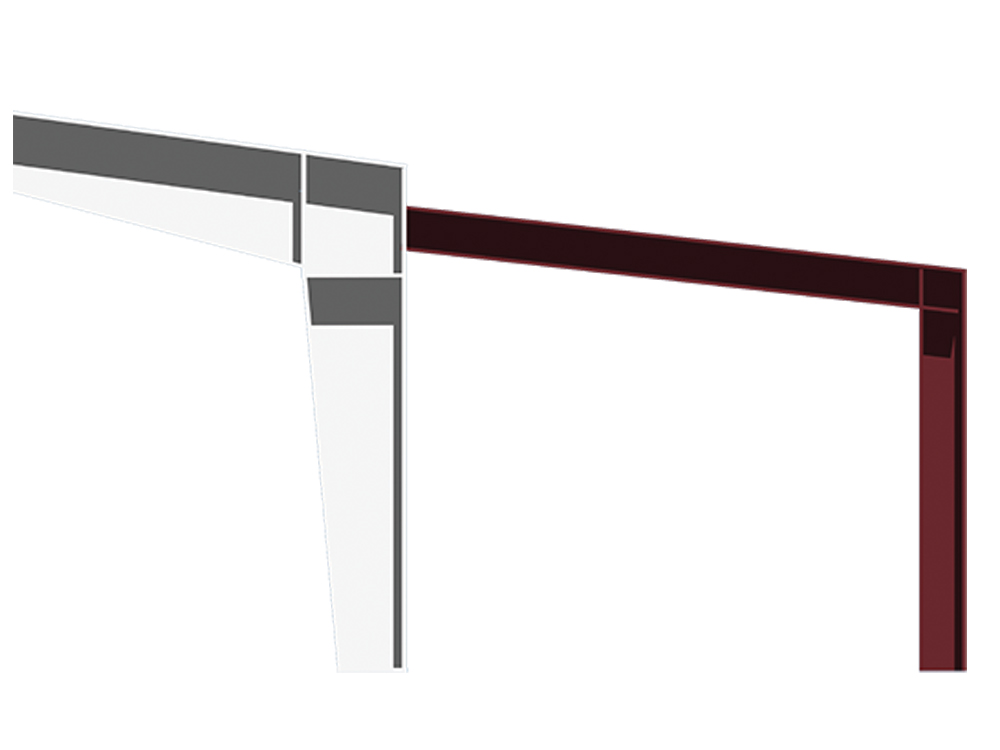

Accent Corners

Our corners can be stacked on top of each other to span the height of any building. They also install lightning-fast and best of all, absolutely no mitering necessary.

Learn More About Accent Corners

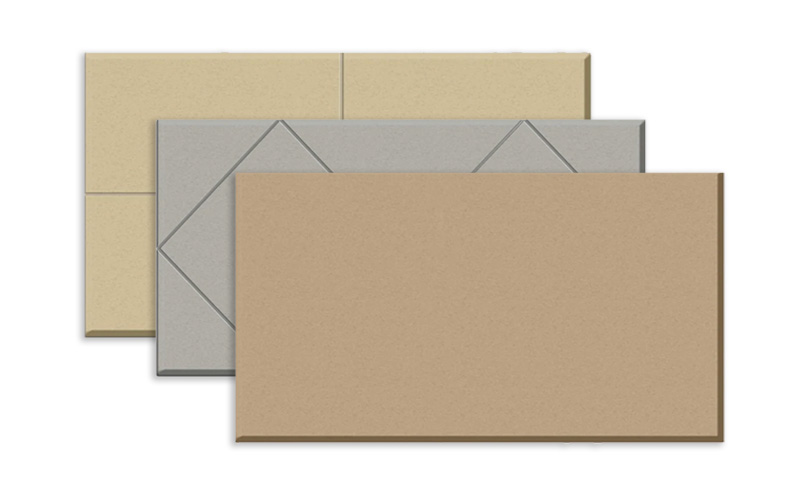

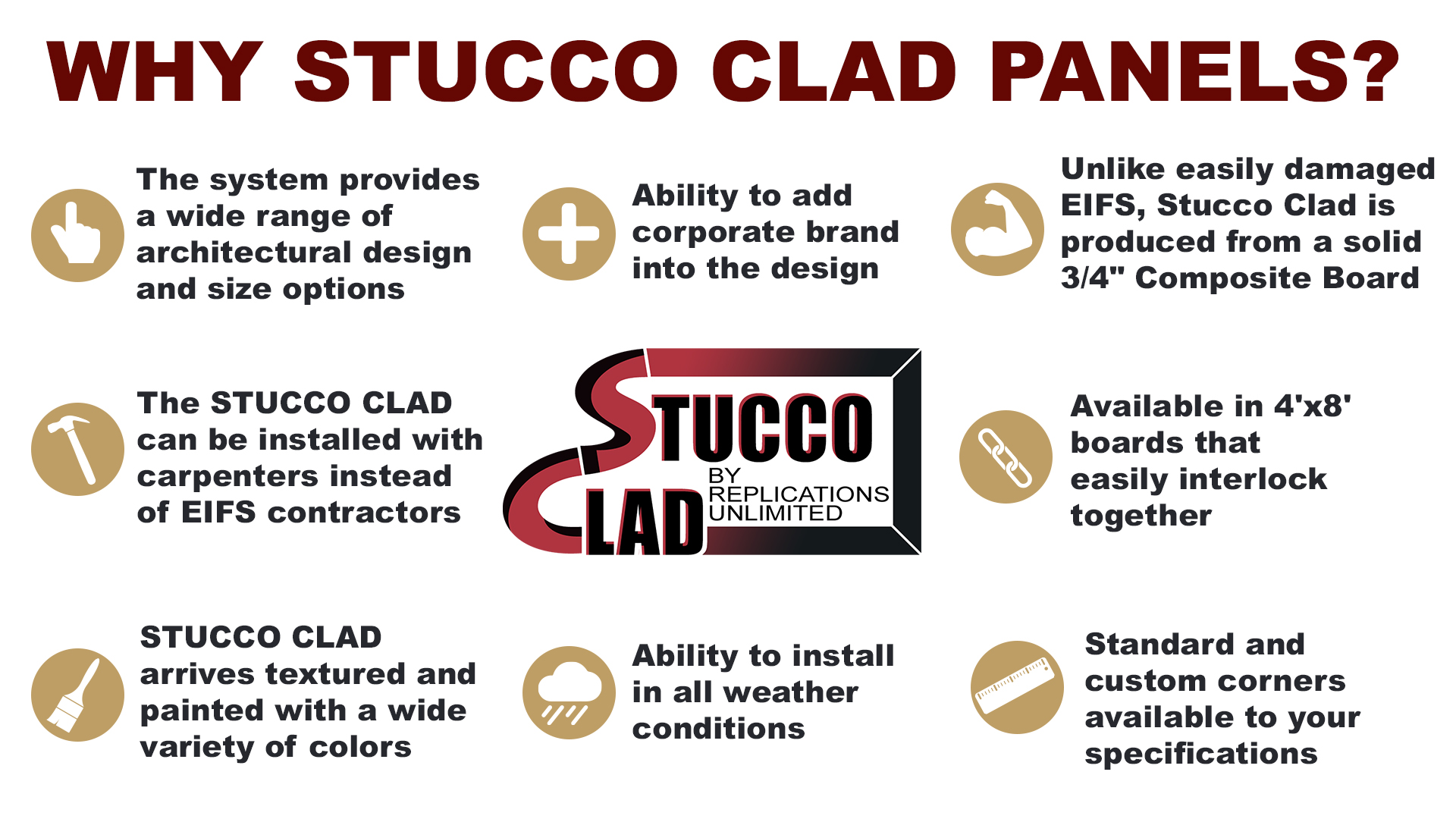

Stucco Clad Panels

Stucco Clad is a synthetic high-density textured architectural panel board that provides a perfect alternative to typical EFIS applications. They are designed to compliment stone, brick and CMU exterior designs which are equally suitable for both new construction and remodels.

Stucco Clad Panels

Stucco Clad is created on a synthetic high-density panel board wherein a CNC computer routers various patterns into the board. After it is primed and painted with standard industry texture and non-textured finishes. With simple interlocking panels, they can be easily be installed by a general contractor rather than hiring a specialized EIFS contractor. This makes Stucco Clad the perfect EIFS alternative for any commercial project both for overall cost and time of installation, without compromising quality.

Stucco Clad provides a wide range of architectural design and size options. In addition, they are tailor made to easily interlock and can be installed with carpenters/general contractors rather than a specialized EIFS subcontractor. It is durable and the perfect way to install sidings in any type of weather conditions and truly customizable to be pre-engineered for any type of building and construction project. Why continue messing with EIFS and EIFS alternatives when you know the problems they cause later down the line. Contractors can now choose Stucco Clad as the top proven EIFS material alternative to finish your project faster without compromise.

Learn More About Stucco Clad Panels

Wainscot Panels

The Wainscot Series are around 36 inch high panels that come with a built-in ledger. With interlocking keys placed end-to-end, create a seamless and natural façade on any surface that can be installed quickly and efficiently.

Learn More About Wainscot Panels

Roll-Up Doors

Commercial Roll Up doors are designed to meet the demands of the self-storage industry. Roll up doors function similar to overhead doors, but are fabricated with a roll coil at the top of the door. This unique design eliminates the need for an overhead door track to maximize the usable space in individual storage units.

Roll up self-storage doors are available in a wide variety of widths and heights to accommodate the size of your storage unit. If you self-storage facility is located in a high wind area, you can request our certified wind load doors. These wind-rated roll up doors are heavier gauge and can be fabricated to your specific wind load requirements.

Learn More About Roll-Up Doors

Steel Walk Doors

We offer Steel Walk Doors, Man Doors and Entry Doors, available in various sizes to accommodate all types of steel buildings. Our Preassembled Steel Door System comes with all of the hardware already installed. Glass lite kits, lever locks, deadbolts, keyless entry locks, panic exit devices and closures can be added to customize your door to your specific needs.

Learn More About Steel Walk Doors

Overhead Doors

Overhead Door Lift Options

To ensure optimal performance and ease of use, selecting the right lift system for your overhead door is crucial. Different lift mechanisms cater to various building designs and operational needs, allowing for seamless door movement in commercial and industrial settings.

Overhead door lifts are available in multiple configurations, including:

Standard Lift: Ideal for doors with ample headroom.

High Lift: Designed for taller openings or applications requiring extra clearance.

Low Headroom Lift: A perfect solution for buildings with minimal overhead space.

Choosing the appropriate lift system enhances safety, efficiency, and overall door functionality. Explore our overhead door lift options to find the best fit for your project.

Overhead doors are available in various heights and widths to accommodate any size framed opening, and can be ordered with insulated or non-insulated options. Glass lites, track options, and weather stripping are available to customize your door.

Learn More About Overhead Doors

Monolithic Foundations

Monolithic foundations are typically used in non-heated structures. They are commonly used in self storage buildings, shops and other buildings with light gauge framing. They can also be used in conjunction with piers for additional column support.

Learn More About Monolithic Foundations

Perimeter Foundations

Perimeter wall foundations are used in buildings that are heated in areas where the ground freezes. This helps prevent the frost from freezing the ground under the slab.

Learn More About Perimeter Foundations

Pier Foundations

Pier foundations are used when a concrete slab floor is not needed. They are commonly used for barns, equipment storage, horse buildings, and in other buildings when cost is a factor.

Learn More About Pier Foundations

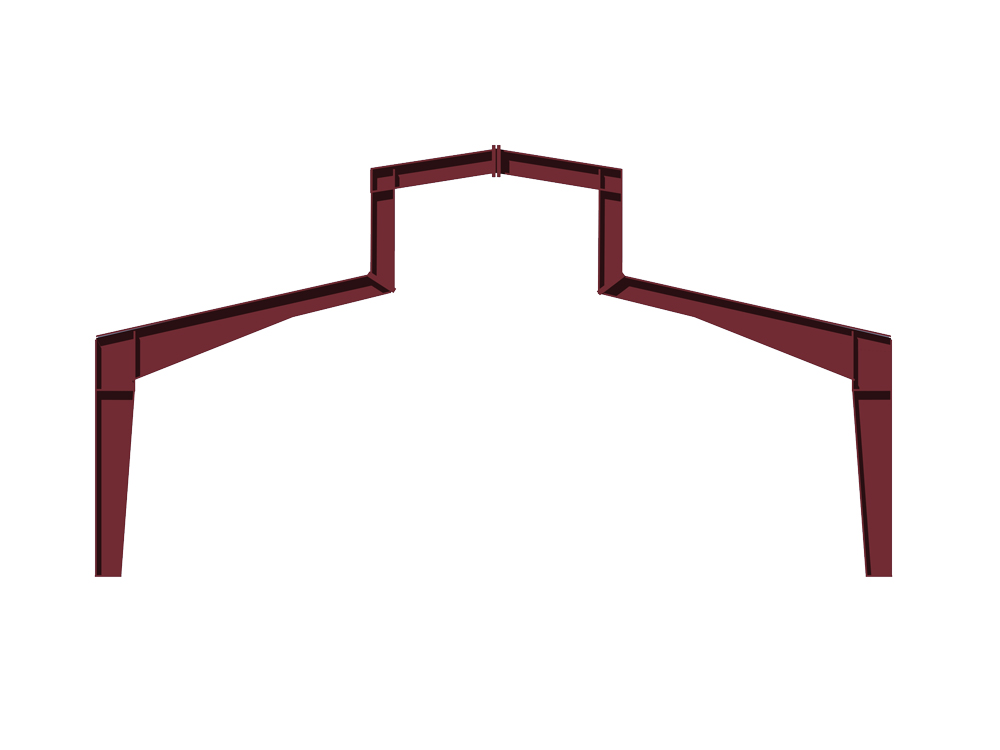

Gambrel Frame

Also similar to a traditional barn structure, the gambrel style roof provides a spacious building that is both visually appealing and fully-functional. The gambrel style can conveniently incorporate your storage needs with a second floor or loft.

Learn More About Gambrel Frame

Straight Column Frame

The straight column frame is primarily used to create an unobstructed interior space. With strength and stability maximized in the straight columns of the steel frames, the design is ideal for garages, offices, or other commercial purposes.

Learn More About Straight Column Frame

Lean-to Frame

A Lean-to Frame can be added onto a building structure to provide a parking area, outdoor storage or a covered porch. Lean-to’s have a similar looking appearance to a single-slope frame but are usually smaller and used only as building additions. Lean-to’s are typically attached to an adjoining column. Lean-to’s are not stand alone buildings.

Learn More About Lean-to Frame

Clerestory Frame

To maximize natural light or air circulation, a clerestory roof is superior solution. With a vertical wall splitting the two sloping roofs, a row of windows or one continuous window is easily incorporated. High above the rest of the steel building, the clerestory reaches the most sunlight while preserving privacy.

Learn More About Clerestory Frame

Multi-story Mezzanine Frame

Ideal for residential structures or buildings with an upstairs office area, the Multi-Story steel building with a Mezzanine is an excellent solution to make the most out of your space. Using a combinations of I-Beams, open web bar joists and columns the floor, the building can provide endless design options.

Learn More About Multi-story Mezzanine Frame

Monitor Frame

With a traditional barn look in mind, the Monitor framed building is used in today’s market for a variety of purposes. What was once used mainly for agricultural buildings, the monitor building is growing in popularity for houses, workshops, warehouses and other commercial buildings. The structural integrity of Sunward’s steel buildings make unobstructed interiors like the monitor possible.

Learn More About Monitor Frame

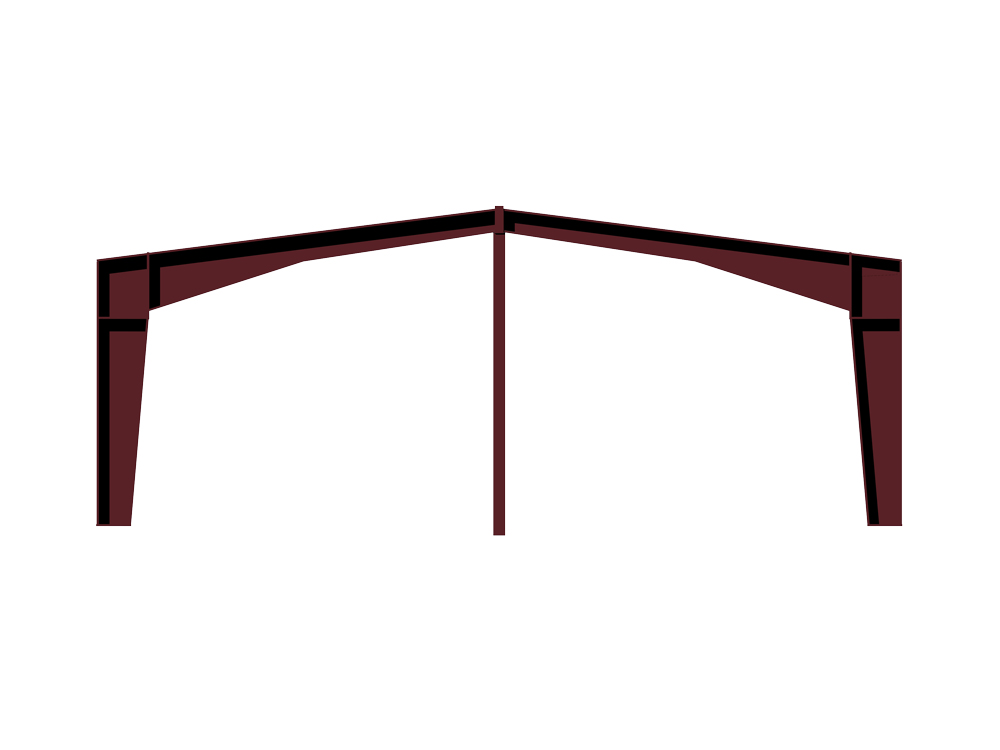

Multi-span Frame

When on a budget and not necessarily needing a clear interior, a multi-span steel building is a viable option. If the building width exceeds 75’ then including interior support columns can help to support the long spans and larger roof loads thus further saving on cost.

Learn More About Multi-span Frame

Single Slope Frame

The Single Slope Framing Style is a good option for adding on to an existing building or for use as a stand-alone building with a slanted roof. The Single Slope design is extremely versatile and provides flexibility in the design of your building or addition. Water can be controlled by draining off the low side and gutters and downspouts are not needed.

Learn More About Single Slope Frame

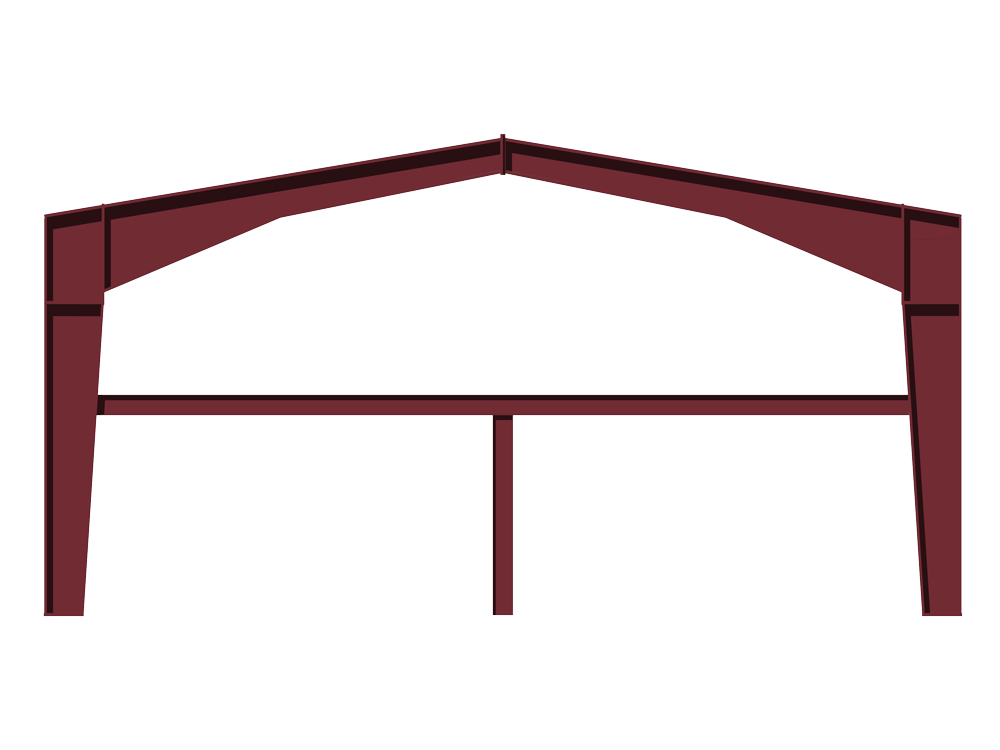

Gable Frame

The Gable Framing System is the most common building frame type. The frame is designed to accommodate all types of steel building applications. A Gable Frame can reach clear-span widths from ten feet up to two hundred feet and roof pitches up to 12:12.

Learn More About Gable Frame

Tabs

Vinyl faced insulation is available with a single 6″ tab preinstalled to each roll. The tabs are an extension of the facing itself which is attached to the fiberglass insulation blanket. These tabs are used to create a seal and add a finished edge at the seams. Double faced tape can also be added to seal the tab to next piece of insulation. Another option is to get a factory pre-applied adhesive on the tab, which the installer can peel and stick to the next insulation blanket. This method provides a clean seal to the seams and creates a vapor barrier.

Learn More About Tabs

Accessories

Looking to DIY? We supply all of the necessary accessories for installing insulation in metal roofs, attaching insulation onto arch building walls, and hanging insulation rolls in your steel building. Insulation Tape, Patch Tape, Thermal break Tape, Steel Banding, Stick Pins and Washers.

Insulation Tape

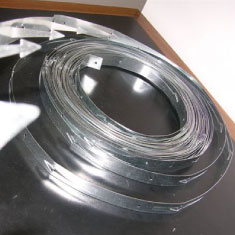

Steel Banding

Insulation Coils

Thermal Insulation Blocks

Sealed N Safe Thermal Blocks are the only tested and certified component of their kind. Thermal Blocks maximize thermal performance and help to drastically improve energy efficiency in steel buildings. The thermal block insulation system is proven to be structurally sound and water tight, making it the the perfect solution for creating a metal building envelope. The system is easy to install and offers fast installation time.

When installing the thermal block system; a Thermal Spacer Block is placed between the metal roof sheet and the roof purlin (or between the wall girt and the sheeting), it isolates the outer shell from the inner frame of the metal building. The 1” foam filled thermal blocks offer a non compressed R-6 performance value, and have been known to increase the insulation performance as much as 2 times in certain buildings. The investments you make with the cost of thermal blocks are known to be paid back through energy savings as little as 12 to 18 months. These calculated savings numbers are based on actual test results. After the initial pay back, you can benefit from a lifetime of savings on energy bills and little to no maintenance costs.

Learn More About Thermal Insulation Blocks

Foam Insulated Panels

Metal Insulated Foam Panels are an ideal roofing and sheeting solution for steel buildings. They are designed to act as a thermal barrier to improve energy efficiency in your building. Insulated foam panels offer high R-Values, (up to R-48) and combine strength, flexibility and outstanding thermal performance. We offer several colors to choose from and optional façade finishes including stucco, embossed, smooth and high rib steel panels. Our insulated panels are painted with long lasting Kynar paint systems that provide little to no maintenance, they are made to withstand weathering and fading from the sun. Insulated Metal Panels are available in lengths up to 50’; end lap joints can be added to cover more space on longer roof runs. Individual Panel thicknesses range anywhere from 2” to 6”, and will achieve R-Values of approximately 7.5 per inch.

Learn More About Foam Insulated Panels

Energy Saver Insulation System

This innovative energy saving insulation system has one of the highest thermal performance results in the industry. The system is made up of a network of steel banding and a seamless energy saver fabric that resists tearing while concealing the secondary structural steel. The energy saver system provides a smooth, yet durable finished interior surface. During installation, a liner system is set in place to begin creation of the building envelope, then two layers of unfaced fiberglass are placed between the purlins and over the top of the purlins, the final step is placing the outside panels. This system offers the best level of thermal performance with one of the highest vapor retarder ratings available. The fabric liner used in the energy saver insulation system is tested and approved to be OSHA compliant for fall protection.

- Meets and often exceeds IECC 2015 energy code requirements

- Provides a clean and finished appearance

- Improves acoustical performance vs. no insulation

- Creates a building envelope

- Continuous insulation method

Double Layer Insulation System

High R-Value Insulation Systems installed in steel buildings improve thermal performance results. The higher the r-value the better, increasing the thermal barrier is the best way to protect against moisture build-up and condensation. Double layer insulation systems are generally chosen where the climate sees regular changes, rainy seasons and snow are a large factor in deciding what r-value you should choose for your insulation system. Local building codes for your area require a specific level of energy efficiency and a higher r-value is required to adhere to the energy codes in certain regions.

Learn More About Double Layer Insulation System

Single Layer Insulation System

When installing a single layer insulation system into a steel building, one layer of Fiberglass insulation is usually placed over the top of the roof purlins and/or on the outside of the wall girts before the exterior panels are secured. Then the vapor barrier facing is placed with the faced side towards the inside of the building, this will give the building interior a clean finished look. The thickest insulation system that can be achieved using a single layer of insulation is 6″; this results in a final r-value of R-19. Anything thicker than 6″ will cause the sheeting material to develop an oil can or wave effect. If you want to achieve a higher R-Value than R-19 a Double Layer System or energy saver system is required.

Learn More About Single Layer Insulation System

5:12 Roof Pitch

A 5/12 roof pitch, commonly termed “5 over 12,” is distinguished by a moderate slope, ascending 5 inches for every 12 inches of horizontal span. This equates to an angle of 22.62 degrees and a pitch factor of 1.08, presenting an optimal balance between design appeal and functional efficacy, particularly for steel buildings. This pitch is advantageous for ease of installation and cost efficiency, providing a practical choice compared to steeper or shallower pitches. It enhances architectural versatility, fitting well with various building styles, from traditional to contemporary, adding a balanced and aesthetically pleasing appearance to steel structures.

Learn More About 5:12 Roof Pitch

4:12 Roof Pitch

A 4:12 roof pitch, commonly referred to as “4 over 12,” signifies a moderate incline where the roof rises 4 inches for every 12 inches of horizontal distance. This results in a slope angle of approximately 18.4 degrees, offering a harmonious balance between aesthetic appeal and practical functionality. This pitch is particularly well-suited for a wide range of architectural styles, providing sufficient slope for effective water runoff without being excessively steep, thus ensuring compatibility with both traditional and contemporary building designs.

Learn More About 4:12 Roof Pitch

3:12 ROOF PITCH

A 3:12 roof pitch, indicating a rise of 3 inches for every 12 inches of horizontal length, translates to an angle of approximately 14.04 degrees. This gentle slope offers a practical balance between aesthetic minimalism and functional roofing requirements. With a pitch factor of 1.03, it represents an efficient design for various architectural styles, particularly modern and minimalist homes, where a subtly sloped roof complements the overall design without overwhelming it.

Learn More About 3:12 ROOF PITCH

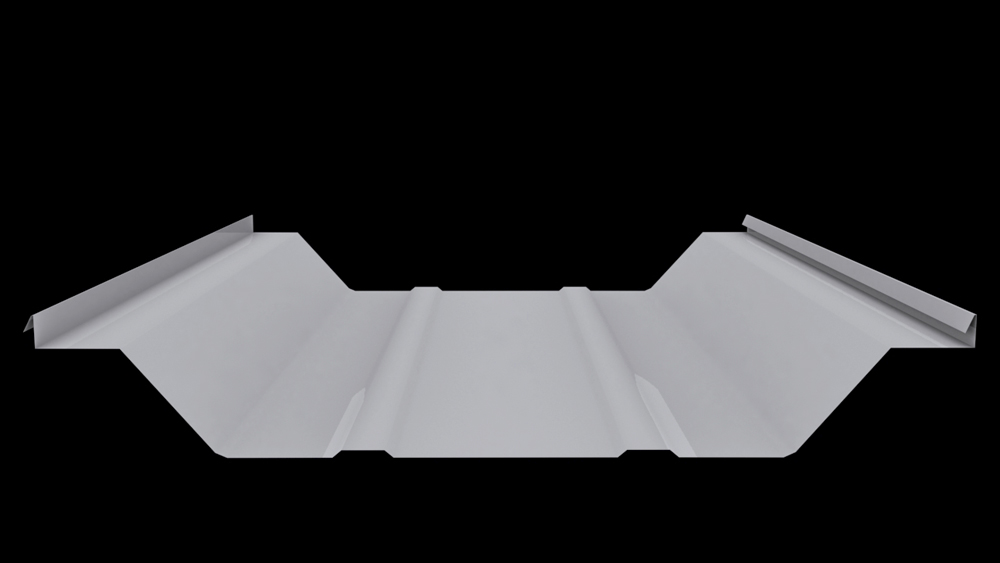

Standing Seam Panel

At Sunward we use a variety of standing seam roof panel options based on building use and architectural specifications and requests. Pictured is a common standing seam roof panel. Separate tools or machinery are required to install standing seam roofs.

Standing Seam Panels come standard in 24 gauge.

Learn More About Standing Seam Panel

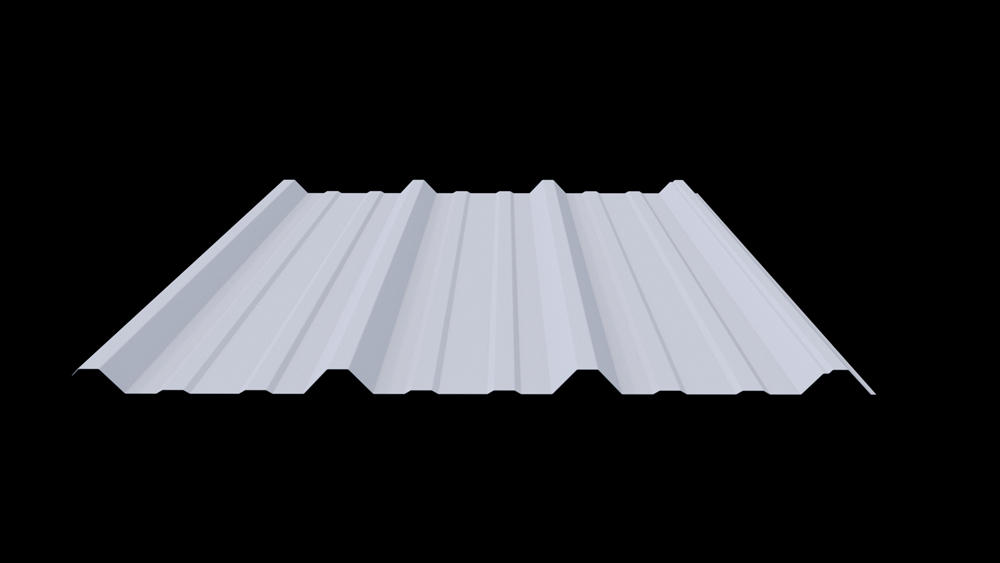

Architectural Panel

Architectural Panels offer an aesthetically pleasing look by reversing the panels to conceal the hardware. They are ideal and often used in buildings when the building owner is adhering to local city zoning requirements or looking for a different look.

The panels come standard in 26 gauge. 24 gauge is available in white and galvalume.

Learn More About Architectural Panel

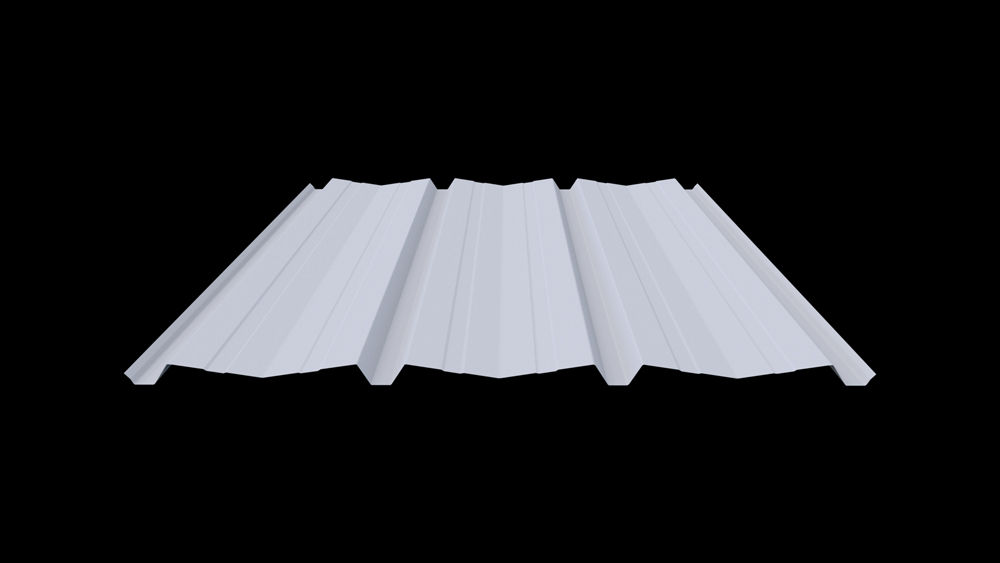

High Rib PBR Panel with Siphon Groove

At Sunward our High Rib PBR Panel is standard with an exclusive Siphon Groove. The Siphon Groove allows the moisture to gather and siphon under the seam, helping to prevent the insulation from getting wet. This is only available with Sunward manufactured products. Outsourced panels will not include a siphon groove.

The panels come standard in 26 gauge. 24 gauge is available in white and galvalume.

Learn More About High Rib PBR Panel with Siphon GrooveWhat Our Customers Are Saying

We are very pleased with our Sunward Steel Building and everyone involved with the company. Choosing Sunward for my building project was the best move I ever made. Sunward’s engineering an...

See MoreGreg Polk

Rocky Mountain Pavememt Maintenance

After researching steel buildings and the many manufacturers, we chose Sunward for several reasons. First; the sales representative, designer, engineers and other employees of Sunward Steel ...

See MoreChris and Brett Watson

Arvada, CO

We are very pleased with our Sunward Steel building and everyone involved with the company. The building arrived on time, fit together well, has a beautiful finish and over four years in use...

See MoreFred and Connie Strotham

Confire Vineyards - Palisades, CO

Choosing Sunward for my building project was the best move I ever made. The insulation package option has saved me money every month. Our building went up fast and we have since added on to ...

See MoreKen Walter

Walter’s Auto Specialties - Englewood, CO

We’ve been in our building now for over eight years. It was an economical building for us to build. The engineered erection prints and anchor bolt plans provided by Sunward helped us get t...

See MoreGeoff Glenn

Three G’s Body & Paint - Littleton, CO

Having built a warehouse before, using Sunward’s steel building system, when it came to making a decision on a building for our van body and truck equipment operation, choosing Sunward was...

See MoreGreg Alfred

Alfred Industries - Henderson, CO

We put our building up ourselves, did not run into any problems. Sunward supplied us a building manual which showed us all the tools we would need and how to get the building foundation squa...

See MoreButch Hartman

CAM Services - Denver, CO

Our “shop” was manufactured in 2005, and has held up thus far. Bringing all THREE companies based out of this shop, many great years and plenty of space. The bosses were able to make it ...

See MoreMulch Mill

WedgCor/Sunward Building which we purchased in Spring of 2012 has been a great addition to our Commercial Property Portfolio. We love running our business out of this facility and get commen...

See MoreBrett Kalias

My building has been up since the spring of 1998 and looks as good as the day it was built, even the paint hasn’t faded. An excellent company to deal with.

Ken Thomas

Excellent customer service! Worked with me more than one project. The project as a whole was completed before listed deadlines. Revised minor parts discrepancies immediately and everything w...

See MoreJerod McClanithan

Thank you for reaching out to us, I was unaware that our building was a Sunward Steel Arena until recently. The arena was previously owned by L.L.Bean and with much anticipation the company ...

See MoreFreeport Equestrian Center

Sunward Steel has excellent project management, ensuring a successful project. They very clearly outlined expectations for budget and timeline, and worked with us to adjust and fine-tune bot...

See MoreKathryn Edwards

I would like to say that the overall experience with Sunward Steel Buildings and their team exceeded my expectations. From the beginning stage of the building planning the owner of the compa...

See MoreDarrell Linkus

My company is in the business of erecting metal buildings in Colorado. We have been installing metal buildings for over 35 years. We have erected most brands of buildings and worked with num...

See MoreRobert Bliss

Featured Sunward Steel Distribution Warehouse Buildings

Steel Workshop Building - Bloomington, IN

June 25, 2023

Steel Warehouse Building - Nicholasville, KY

April 7, 2023

Steel Warehouse Building - Las Vegas, NV

August 7, 2019

Prefabricated Steel Warehouse - Frederick, MD

January 18, 2020